Do you really know the specifications of these graphite raw materials?

Date of release:2019-05-14 Author: Click:

High purity graphite

High purity graphite generally refers to the graphite with carbon content of more than 99.99%, which can be divided into coarse particle structure, fine particle structure and ultrafine particle structure in the structure of three categories, high purity graphite is widely used in single crystal silicon furnace.Integrated circuit base material is mainly heavily sb-doped silicon chip, the current number of growth process mainly adopts czochralski (CZ) method and other methods and magnetic field czochralski method (MCZ), area (FZ) method and double crucible pulling method, the global electronics industry with draw monocrystalline silicon accounted for about 80% of the monocrystalline silicon total dosage, pulling of monocrystalline silicon furnace graphite pieces of consumables, high purity graphite materials processed into pulling of monocrystalline silicon furnace heating system.In 2005, China needs about 800t graphite for single crystal furnace.

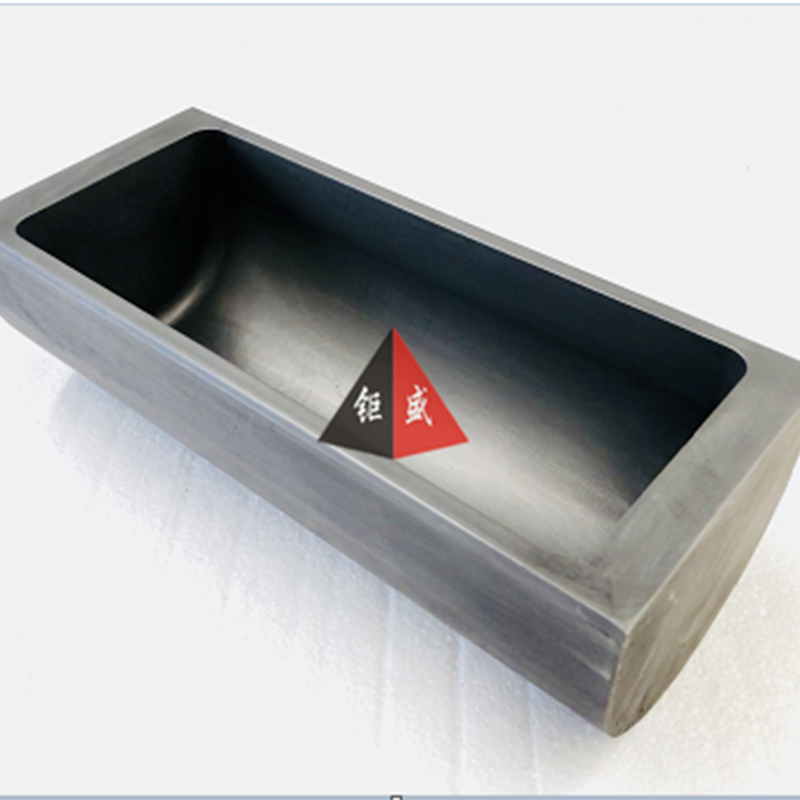

Another important use of high purity graphite is processing into various crucible, used for production, rare metal or high purity metal, non-metallic materials.The graphite electrode used for spectral analysis is also a kind of high purity graphite, which can be used for spectral chemical analysis of all elements except carbon.The impurity element content of the finished products should be no more than 6*10-5. When preparing standard samples in spectral analysis and collecting impurities by chemical methods, it is necessary to use spectral pure charcoal powder or spectral pure graphite powder. The impurity content of these two kinds of high purity materials should be 6*10-5.In some applications, 99.9995% carbon is required and the total ash content is less than 5*10-6.The forming methods of high purity graphite are extrusion forming, molding forming and isostatic forming.

Graphite for nuclear energy

Graphite is one of the slowing and reflecting materials used to build nuclear reactors, which were graphite reactors in the early days.Used as structure material of nuclear reactor with graphite in the selection of raw materials, process control, finished product inspection is more exacting than the graphite electrode, are much more expensive, a nuclear reactor with graphite must meet the following performance: to slow the absorption of small, good high temperature strength, high thermal shock resistance, deceleration performance is good, under the irradiation of fast neutron size stability, impurity content is very few.The content of boron, cadmium and other elements easy to absorb neutrons should be strictly controlled.

Nuclear graphite must have higher bulk density M because of graphite for fast neutron slowing effect depend on fast neutron on the collision of the carbon atoms to realize carbon atoms per unit volume of M M M cut fruit, the better the more so the bulk density is one of the main indicators of nuclear graphite M volume density is also related to porosity and permeability of graphite directly M to avoid nuclear fuel and the loss of the heating medium M will be reduced to a certain level of porosity and permeability.The mechanical strength of graphite is also related to its volume density. The volume density of core graphite used in general graphite stacks is between 1.7 and 1.75g/cm3.

Nuclear reactor for electricity generation is mainly do not need to use graphite pressurized water reactor, but experts expect high temperature gas cooled reactor is very promising, the high temperature gas cooled reactor requires a lot of 9 senior graphite materials in high temperature gas cooled reactor due to using helium as a coolant, carbon and ceramic material was used as the fuel cladding material, as the reduction material with graphite or carbonaceous materials and structure of furnace core material, can put close to five high temperature gas exported outside the reactor used as energy.

Isotropic graphite

Although international definition of isotropic graphite remains to be further clear, usually measuring product diameter direction and some physical performance index of the length direction and its ratio was calculated with the ratio of thermal expansion coefficient, said some simpler is the ratio of resistivity, said its differential than within the range of 1.0 ~ 1.1 called isotropic products, more than 1.1 is called anisotropy products.Large isotropic graphite produced by Japan and other countries with advanced industrial technology by isostatic molding has a diameter of 1.5m, a length of 3%, a volume density of 1.95-2.0g/cm3, and an anisotropy ratio of 1.05.Isotropic graphite in addition to the use of general petroleum coke, but also use modified asphalt coke, natural asphalt coke, oxidized petroleum coke, not calcined raw petroleum coke, natural graphite.