What are the main applications of graphite mold?

Date of release:2019-07-01 Author: Click:

In recent years, graphite with its good physical and chemical properties has gradually become the preferred material for mold making, graphite mold is widely used in various fields.Below, we have a look at the main application of graphite mold which.

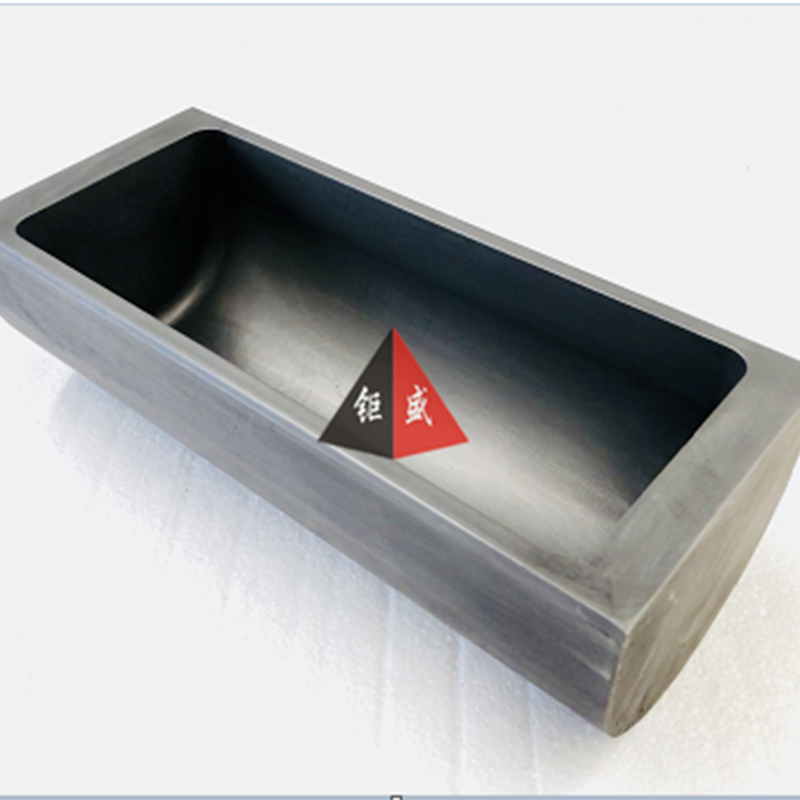

1. Graphite molds for nonferrous metal continuous casting and semi-continuous casting

In recent years, advanced production methods such as direct continuous (or semi-continuous) manufacturing of bar or pipe from molten metal state are being popularized at home and abroad.Domestic copper, copper alloy, aluminum, aluminum alloy and other aspects have begun to use this method.Artificial graphite is considered as a suitable material for continuous casting or semi-continuous casting of nonferrous metals.Production practice has proved that the adoption of graphite mould, because of its good performance of thermal conductivity, thermal conductivity performance determines the speed of solidification of the metal or alloy), mold good self-lubricating performance factors, not only make the casting speed, and as a result of the ingot size accurate, smooth surface, uniform crystal structure, can be directly for the next working procedure of processing.This not only greatly improved the yield, reduce the loss of waste products, but also greatly improved the quality of products.

2. Die for pressure casting

Artificial graphite materials have been successfully used in pressure casting of nonferrous metals.For example, zinc-alloy and copper-alloy castings made from pressure casting molds made of artificial graphite materials have been used in automobile parts and so on.

3. Graphite mold for centrifugal casting

Graphite mold has been successfully used in centrifugal casting.In the United States, bronze sleeves have been centrifugally cast using artificial graphite molds with wall thickness of more than 25 mm.In order to prevent the loss of artificial graphite mold, some measures can be taken to prevent oxidation.After casting a certain number of castings, if the inner surface of the mold is found to be burnt, the size of the inner hole of the mold can be enlarged to make it suitable for casting large size casing.

4, hot pressing die

The artificial graphite hot pressing die is used in the pressing sintering of cemented carbide with the following characteristics: first, if the pressing temperature increases to 1350-1450 degrees, the required unit pressure can be reduced to 67-100 kilograms force/square centimeter (that is, 1/10 of the cold pressing pressure);Second, pressing and heating are carried out in the same process, and compact sintered bodies can be obtained after a short time of sintering.

5. Graphite mould for glass forming

Because stone graphite material with chemical stability, susceptible to infiltration of molten glass, will not change the composition of the glass, graphite material thermal shock performance is good, the characteristics of small size change with temperature, so in recent years become indispensable in the glass manufacturing mold material, it can be used to manufacture glass tube, pipe, funnel and other forms of special shape of glass bottle mould.

6. Sintered graphite mold and others

The sintered mould and support for manufacturing transistors are widely used by using the characteristics of the artificial graphite material with minimal thermal deformation, which has become an indispensable material for the development of semiconductor industry.In addition, graphite molds are also used in cast iron molds, durability molds for various non-ferrous metals, cast steel molds, heat resistant metals (titanium, zirconium, molybdenum, etc.) and aluminum-thermal welding molds for rail welding, etc.

The address of this article:http://enjusheng168.mycn86.cn/news/426.html

Key word:Graphiteplate,Graphiterod,Graphitecrucible

The next one:Application fields of natural graphite and artificial graphite