Graphite mold, crucible and other graphite products CNC processing how to choose the right tool

Date of release:2019-07-11 Author: Click:

With the development of high and new technology, the graphite material manufacturing process continues to improve, the graphite high-speed milling machine came into being in the market, can meet the needs of different processing graphite materials emerge in endlessly, CNC edm machine graphite discharge performance has been comprehensively improved.

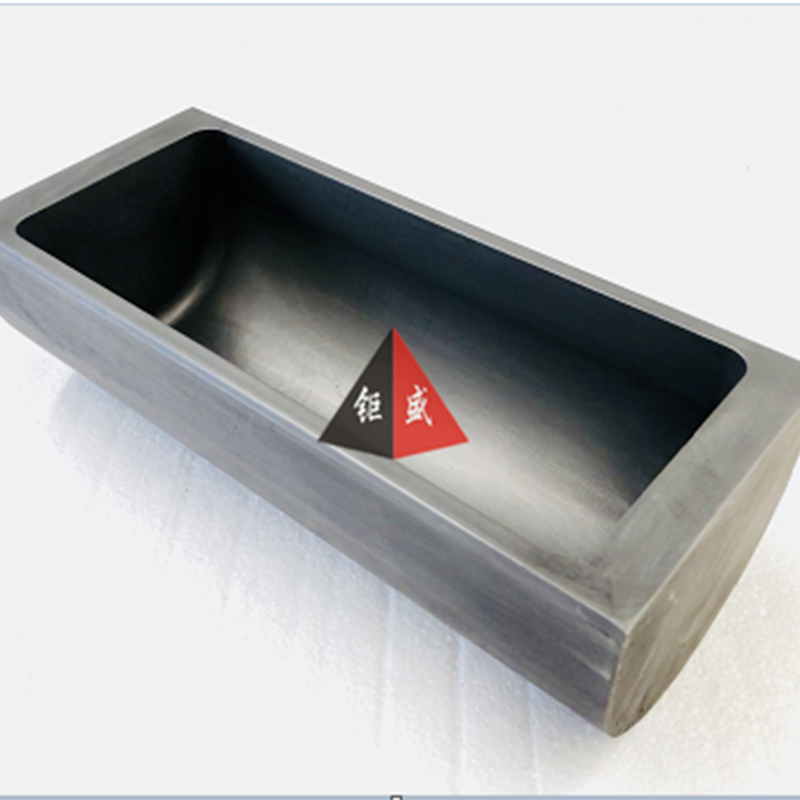

Graphite because of the high temperature strength, low thermal expansion coefficient, good processability, and good thermal and electrical conductivity, currently widely used in the graphite electrode, graphite mould, graphite crucible, 3 d hot bending mould (mainly mobile phone glass hot bending modulus) graphite products, such as in Europe, leading manufacturing technology adopted by more than 90% of electrode materials, graphite mold enterprise.

How to choose the right graphite cutting tool?

1. Tool materials.Tool material is an important factor that determines the cutting performance of a tool, which has a great influence on the machining efficiency, machining quality, machining cost and tool durability.The harder the tool material, the better its wear resistance, but the higher the hardness, the lower the impact toughness, the more brittle the material.Hardness and toughness are contradictory, which is a problem which tool material should solve.For graphite cutting tool, ordinary TiAlN coating can be selected on the material toughness is relatively good, that is, the cobalt content is slightly higher;For diamond-coated graphite cutting tool, the hardness is relatively high, that is, the cobalt content is slightly lower;For polycrystalline diamond PCD tools, coarse-grained brands with better wear resistance, such as CDW025 and CDW302, can be selected.

2, the geometric Angle of the tool.Graphite special tool to choose the right geometric Angle, help reduce the vibration of the tool, in turn, the graphite workpiece is not easy to collapse.

3, the coating of the tool.Diamond coating tool has the advantages of high hardness, good wear resistance and low friction factor. At present, diamond coating is a better choice of graphite processing tool, and can better reflect the graphite tool performance.

4, the tool edge passivation.The purpose of tool passivation is to solve the above grinding of the knife edge micro notch defect, make its front value reduce or eliminate, to achieve smooth, sharp and durable purpose.

5, the machining conditions of the tool.The choice of the right processing conditions has a considerable impact on the life of the tool.

Based on the above points, the tool material, geometric Angle, coating, edge strengthening and mechanical processing conditions, in the service life of the tool plays a different role, without one cannot, complement each other.A good graphite cutter, should have a smooth graphite powder chip discharge groove, long service life, can be deep carving processing, processing costs can be saved.